Our Services

Vibration Analysis Services

The “Cornerstone of Predictive Maintenance” which stands in sharp contrast to the historical run-to-failure type of maintenance practice. Numerous studies have shown that on average, the cost to industry for maintenance will be reduced by more than 50% if a predictive maintenance program is used instead of run-to-failure.

Thermographic Scanning

Thermography or infrared scanning service provides “Early Warning of Potential Electrical & Mechanical Failures” in your systems, equipment, structures and etc. Importance of identifying and rectifying equipment issues before they become problems are a critical part of averting loss and maintaining uninterrupted service.

Oil Analysis Services

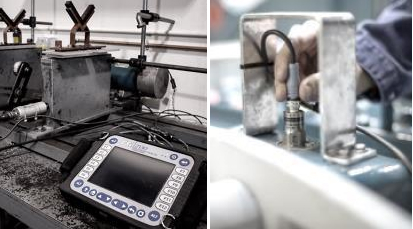

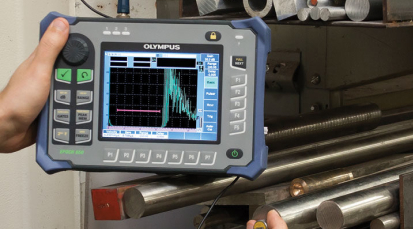

Ultrasound inspection analysis

Used primarily for “Leak Detection, Steam Traps, Bearing Monitoring, Acoustic Lubrication & Electrical Inspection”, ultrasound Inspection have proven to save tens of thousands of dollars in premature failure detection, elimination of downtime, increased productivity, and overall replacement costs.

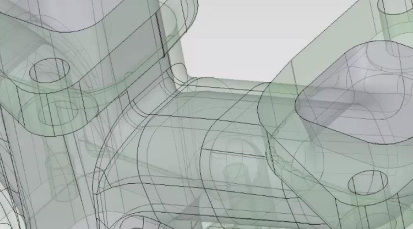

Modelling & Simulation services

“A Picture Worth A Thousand Words”. This is especially true when it comes to understanding some of the complex, dynamic problems that plague operating machinery.

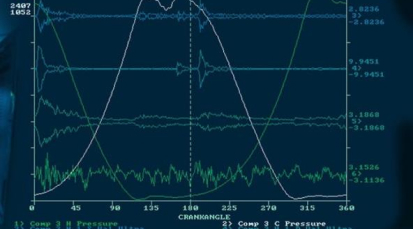

Performance Analysis Services

Field testing of gas turbines, compressors, reciprocating engines and other machineries has become increasingly common due to the need to “verify efficiency, power, fuel flow, capacity etc” to ensure optimized performance and evaluation of machine’s condition.

Partial Discharge Testing Services

Dewatering & Purification services

“Water effects both the oil & the machine”. By understanding the coexistence of water in Oil States, it will extend the equipment life.

Flushing & filtration services

Particle contamination in Lubrication Oil would affect on component longevity. This service is provided to improve in particle contamination according to ISO Cleanliness Code and ensure the Lubrication Oil acts as a best sealant to mechanical components.

Interested To Know More About Our Services?

Fill in the form and lets get in touch!